Kawasaki

Expanding horizons with intelligent track maintenance support

At a glance

Kawasaki Heavy Industries, Ltd. (Kawasaki) has been manufacturing large machinery for more than a hundred years. Now the company is taking on a new challenge: making it easier and less expensive for US rail companies to keep their tracks safe.

Impact

With Intelligent Products that combine hardware and software, the Kawasaki team is expanding their horizons for innovation. As early customers field-test these solutions and see the results in performance and cost savings, the way is clear for Kawasaki to take these initial efforts further.

Key Services

Industry

Mobility

Key Technologies / Platforms

- Microsoft Azure

- Azure Sphere

- Databricks

- NVIDIA Jetson Orin

- NVIDIA cuOpt

The US has the biggest national rail network in the world, with around 130,000 miles of railroad track. Keeping that much track in safe condition, when it’s spread out over 3.8 million square miles of terrain, is uniquely difficult. And that difficulty contributes to more than 1,000 train incidents per year, which disrupt service for freight and passengers.

By contrast, the rail network in Japan sets the international standard for safety, and it’s renowned for technological innovation in autonomous track inspection. Since Kawasaki Railcar Manufacturing (KRM) already supplies rolling stock to North America, the company saw a prime opportunity to add track maintenance support services to its offering for US railway companies.

Non-digital operations are inefficient and hard to scale

Historically, track inspection has been a labor-intensive process. It interrupts freight operations because railways must run dedicated inspection cars that cannot carry freight. It’s hard to scale, because inspectors must be well-trained to recognize small but critical issues when visually inspecting rails, fasteners, ties, and ballast. They also need to follow safety regulations and meticulously document their findings. Simply put, traditional track inspection is a manual and inefficient task.

Kawasaki as a company faced some of the same challenges as the rail industry. Its growth was being held back by the limitations of delivering physical products, which are not scalable the way digital products and services are. So, expanding its track technologies—while developing the capability to create those technologies—puts Kawasaki and its customers into a new frontier of potential.

Since Kawasaki had less experience in software engineering, it needed to find a partner with software expertise comparable to its hardware expertise. If the rail division could effect a digital transformation to unlock more value for its customers, that success could then be replicated throughout Kawasaki.

The advantages of pioneering the digital future

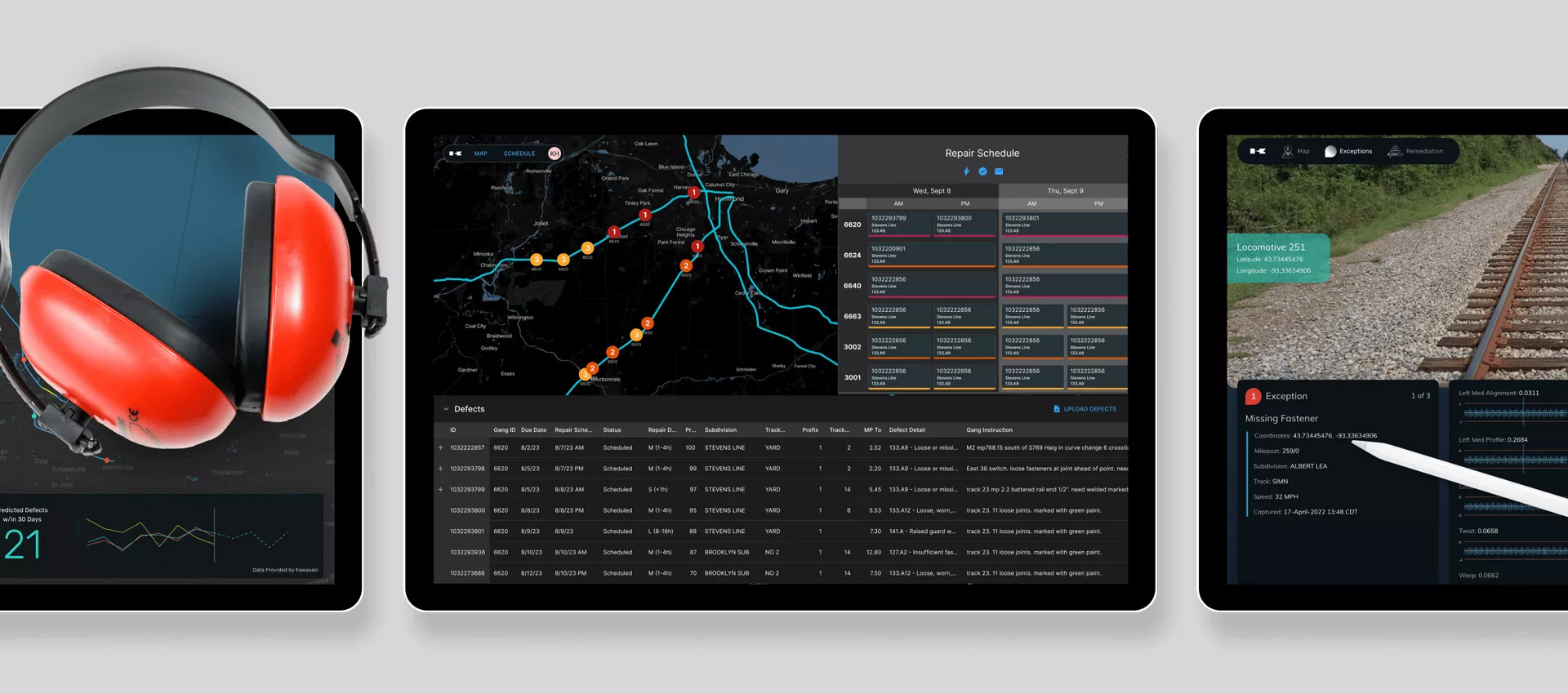

For the first leg of its journey into integrated software, Kawasaki has developed a digital platform that leverages AI/ML on the edge and interfaces with IoT track inspection devices such as digital cameras, lasers, and gyro sensors. The platform collects and analyzes rail data using modern cloud computing, and automated training intelligently improves the ML models on the edge.

Rail companies that adopt the platform for automated track maintenance services can see an increase in safety and efficiency, and a decrease in costs for inspection. Connecting sensor data with on-the-ground expertise of railway staff ensures that valuable human capital isn’t left behind in the pursuit of automation.

The rail data platform represents a promising new revenue stream for Kawasaki in the tens of millions of dollars. Even greater is the growth potential across Kawasaki when this digital strategy is implemented in other lines of business, such as robotics and hydrogen.

To support this endeavor, Kawasaki has established a new internal Agile engineering team. For a company that started with zero software engineers, it’s a testament to their diligence that they now have a team of 12 to 15 and are successfully delivering working software. Kawasaki will be more resilient and prepared for the digital-first future because of this capability.

The transformative impact of Intelligent Products

How did Kawasaki reach this point in a few short years? To begin, key Kawasaki employees came to the Slalom Build Center in Seattle. Together we undertook the Discovery phase to determine a product vision that would create value for rail customers and for the Kawasaki business, with an achievable scope.

Kawasaki had been building momentum with its Geometry system, which uses sensors to detect irregularities in the three-dimensional positioning of railway tracks that need to be corrected or repaired. This system is already commercially available and was an important proof of concept for the overall strategy.

Agile development on additional platform components started with Kawasaki and Slalom team members in both countries, Japan and the US. The two-way transfer of knowledge has built respect as hardware and software experts work together to solve strategic and engineering problems.

The next component, the Fastener system, uses computer vision to inspect the spikes, clamps, clips, and other fasteners that affix the track to the rail ties. Software running on edge devices performs powerful image recognition, comparing the data with the railroad’s rules and Federal Railroad Administration rules to flag defects. It then sends that data to the cloud to produce a list of defects so customers can understand the condition of the track.

Another groundbreaking component, the Maintenance Advisor, uses AI/ML to compile repair needs and plan optimized routes for carrying out maintenance with minimal cost and disruption to the rail system. This component is where the power of Intelligent Products comes to the fore, turning mountains of data into smart, actionable directives that make the most of repair efforts.

Full steam ahead for modern manufacturing

Although there have been challenges for both Kawasaki and Slalom Build in overcoming cultural and language differences in our collaboration, there has been great value for both companies in working together and learning from each other. Kawasaki engineers recognize the critical opportunity for themselves and their company in expanding their skills and adapting Agile practices to the Kawasaki culture.

As early customers like Union Pacific and BNSF Railway field-test these track maintenance solutions and see the results in performance and cost savings, the way is clear for Kawasaki to take these initial efforts further.

With the skill to augment its world-class hardware with valuable software solutions, Kawasaki has switched over to a track leading to competitive success.